Goodness pressure is important in continuous flow. In fact, one of the major advantages of flow vs batch is how easy it is to apply pressure. The main benefit of pressure for a homogeneous liquid reaction is that the solvent can be heated above its standard boiling point, allowing you to give the kinetics of your reaction a bit of a kick up the proverbial and reduce the time needed inside the reactor, and thus, increase your throughput. It does go without saying though that this approach only applies to chemistry robust enough to take it, and those who are at the final stage of a synthesis of a large natural product, probably need to take things more gently.

That said, there are other reasons that pressure is important – we can discuss thermodynamic, physical chemistry functions like the Gibbs volume of activation if you like, but I think before we need to think too hard about that, pressure has more immediate benefits. Preventing gas evolution from reducing residence times is key to maintaining good conversions, and pressure is vital in gas/liquid reactions for making sure the liquid is saturated with the gas for the reaction to take place.

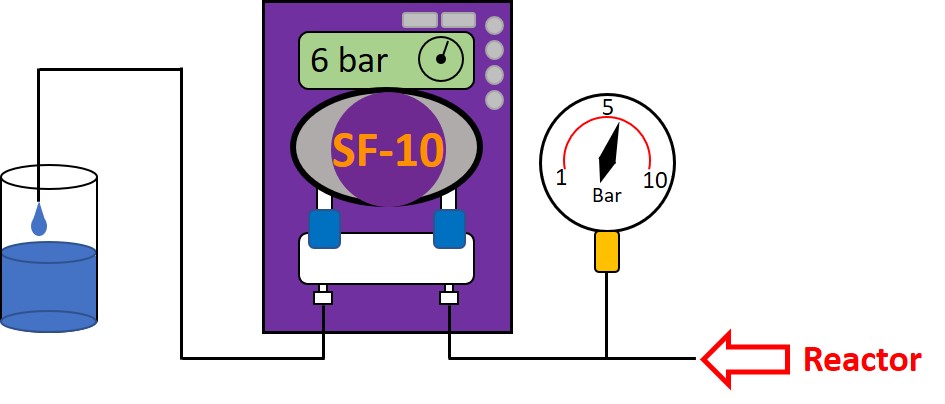

But, there is a problem. Solids, particulates, precipitates of any kind can cause a real problem with needle and seat-type back-pressure regulators, causing inconsistent pressure management at best, and blockages at worst. Enter the peristaltic BPR. The SF-10 pump uses the Vapourtec V-3 pumps and can run as a pressure regulator. Now, the maximum pressure is 10 bar, but that’s more than enough to superheat most solvents quite a long way and the continuous release of pressure, instead of the “open-closed” binary state of a needle BPR, allows for much smoother, more consistent pressure control. The real piece de resistance though is that the SF-10 can handle solids. Not just the odd crystalline precipitate either, I’ve used these pumps to control the pressure of slurries loaded up to 100 mg/ml without any trouble and now it’s my go-to method of controlling pressure, simply because I know that it will just keep working even if I haven’t got my down-stream solubility quite right (which I never have, by the way).