“Fatal if inhaled”. There. That got your attention.

It certainly got mine! I was preparing the COSHH assessment for a recent application note when I saw that alarming statement, which on the SDS is then followed by the rather helpful advice “do not breathe fume/vapour”, just in case you hadn’t fully understood the concept of fatal if inhaled…

Happily, things like this are made a little simpler with flow chemistry. The plan was to carry out the photochemical bromination of a range of different substituted toluenes, using molecular bromine in solution, and see how easy it would be to increase the throughput of the reaction. As the bromine does present a fairly significant hazard, Dr Roger Moses joined me in the lab to share his experience and provide Devon vs Cornwall related banter (cream and then jam, obviously).

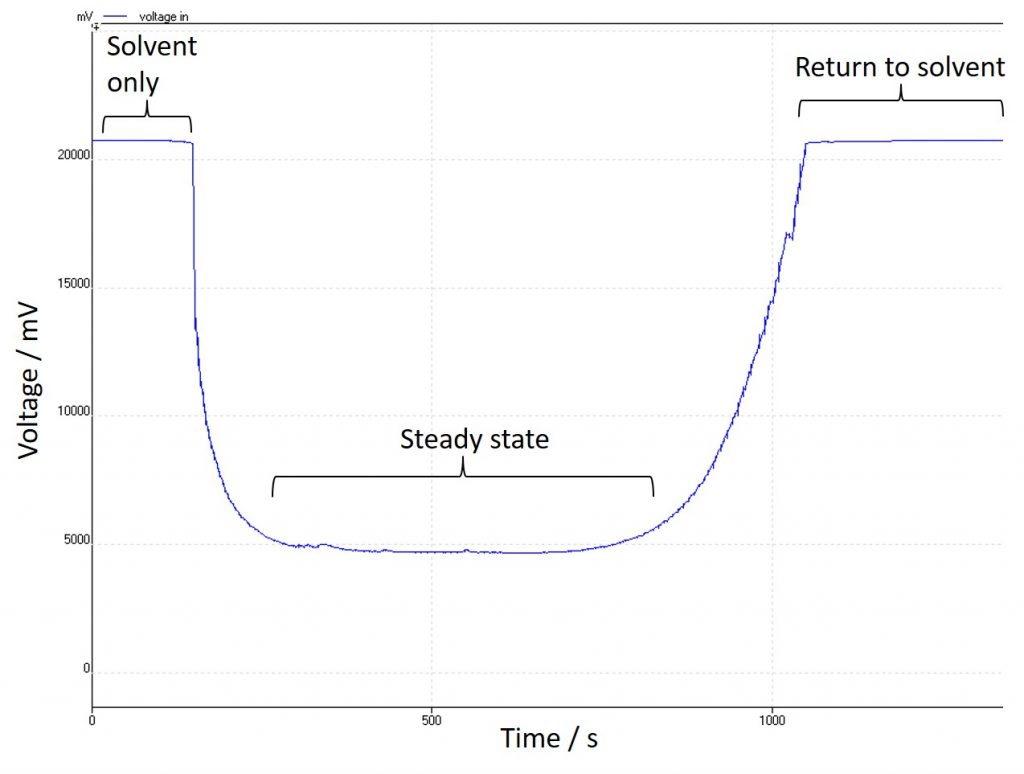

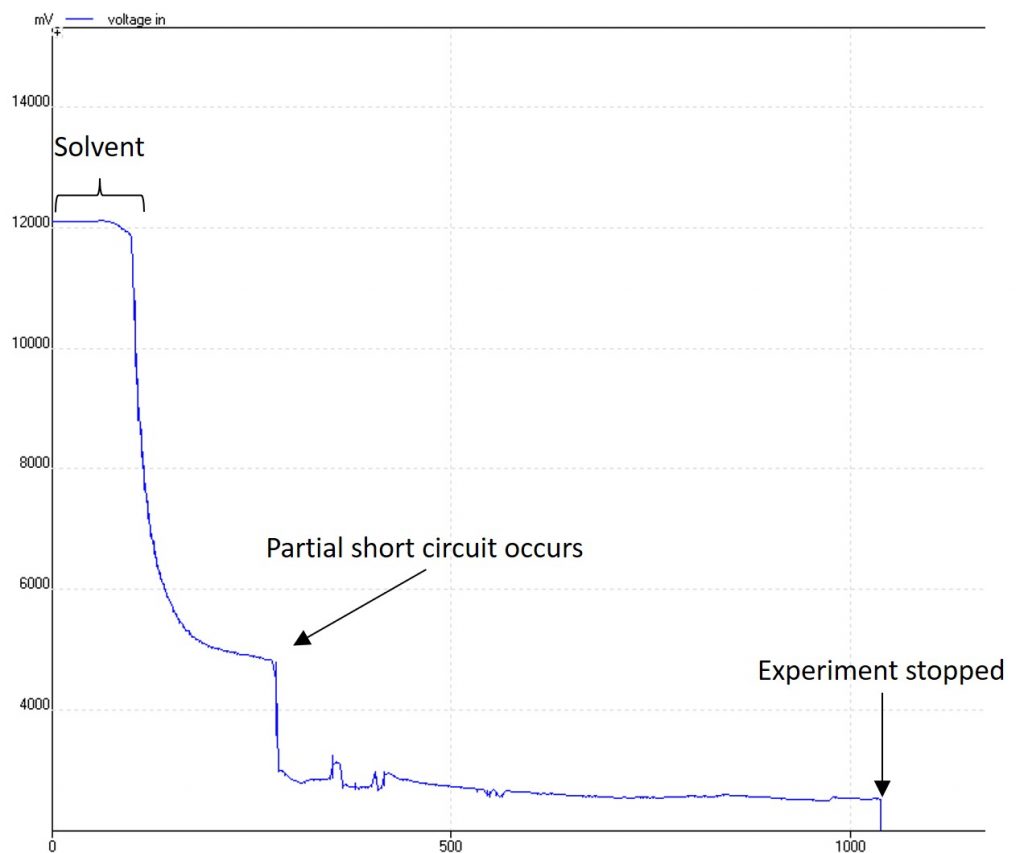

With the bromine in solution, which when I think about it I ought to have made using an SF-10 to deliver the bromine instead of using a Pasteur pipette, working with it in flow was very straightforward. It was very pleasing to see the orange-brown reagent mixture going into the reactor and colourless product coming out of the other end, although thick gloves were needed for everything, as the HBr generated in a stoichiometric amount, can fume off of the product vial. A little wash with some thiosulfate solution to pick off any bromine that might still be lurking about, and then onto the HPLC to get a feel for what’s going on. As far as boosting throughput goes, this really was about as easy as it gets; the UV-150 is very efficient, so even with residence times of just a minute we were seeing conversions of 80% or so. We quickly got up to around 15 grams per hour, and then chickened out pushing any further – the benzylic bromides are well known for their lachrymatory properties, and cleaning up a bunch of essentially tear gas didn’t seem like a fun way to spend the afternoon.

For more information about Vapourtec, click here.

Return on the 27th of October for the next blog about using n-butyllithium in continuous flow